Stainless steel strapping is fast catching up with other strapping solutions commonly used in the packaging industry. Unlike conventional steel straps, the presence of chromium makes this alloy capable of successfully weathering tough conditions. Stainless steel is also highly corrosion resistant. It does not rust or leave marks on the package, which is a big win over steel straps, and a relief for its users. This makes it the ideal strapping solution and hence often chosen over steel strapping.

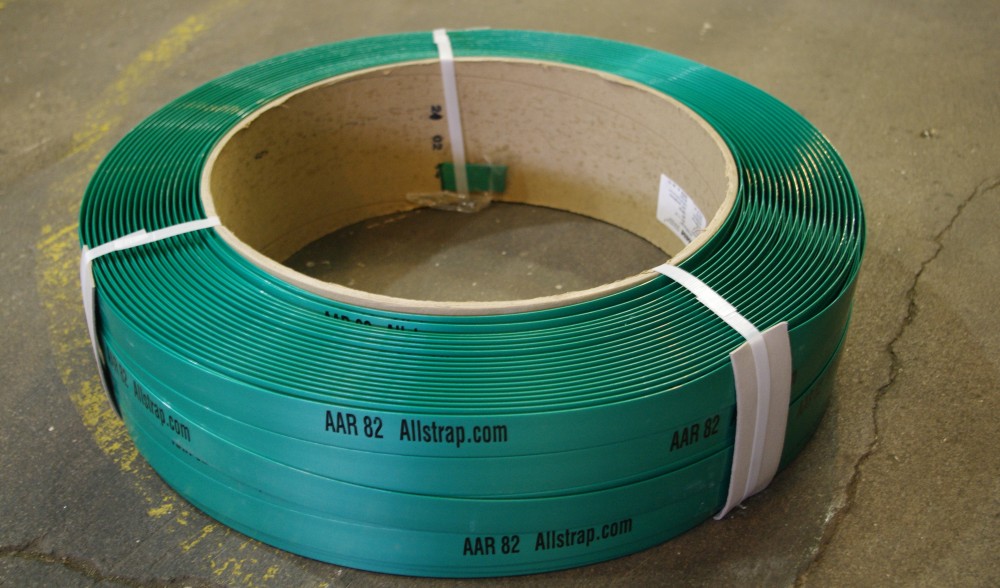

Stainless steel straps are typically produced by manufacturers as wound stainless steel coils or bands, and can additionally come with a self-dispensing unit for easy packaging. The coils itself vary in length and thickness, with 100ft and 200ft coils being extensively used in the industry. The straps are used for insulation related work, securing sign boards and similar light applications. Stainless steel strapping also provide high tension and are easy to weld. This makes them quite a popular choice in telecommunications, petroleum industries, civil engineering related construction sites and other non-commercial industrial applications.

In addition to using conventional stainless steel, manufacturers also benefit from using varied stainless steel types, further enhancing their usability. For instance, Type-201 stainless steel straps contain chromium, nickel and manganese, providing increased strength and first-rate mechanical properties. They are uniformly elongated with improved stretch ability. All this makes them the perfect choice for heavy duty applications.

Type-304 stainless steel straps are yet another popular packaging solution commonly used in outdoor industrial applications. They are treasured for being corrosion resistant and immensely easy to weld. Regardless of the stainless steel type used, manufacturers are increasing their commitment to safety and precaution by producing steel straps and coils with rounded edges. This makes them safe to handle and hence reduces accidents at sites.

The downside of using stainless steel strapping is its cost. The alloy is more expensive than conventional steel, and hence low budget industries continue to stick to the older steel strapping solutions despite its disadvantages.

Allstrap is a popular dealer providing various products to guarantee complete your stainless steel strapping solution. You can kick start your search for the perfect strapping solution for your business by contacting Allstrap today. Or, visit their website at allstrap.com to browse MIP Tools and banding solutions!